The Cutting Edge in Cheese-Making

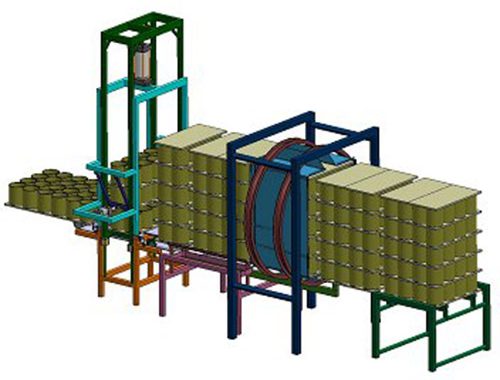

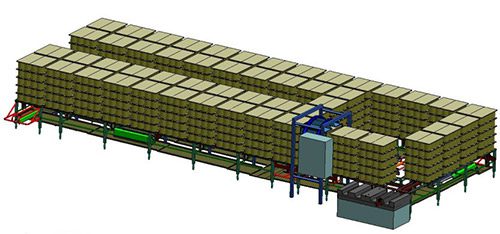

The days of churning butter are over. D.R. Tech is reimagining the future with our rotator line systems. We build and integrate our rotator line systems through a process involving both mechanical and electrical (low voltage) installation and rigging. We back it all up with a host of other services: field service, refurbishing, spare parts provision, and functional testing. These are the ways we provide our customers a high and consistent quality product.

Read More ▼Designed to run using electric, hydraulic, or pneumatic powering systems, and composed of stainless steel 304/316, plastics, and rubbers, our USDA-certified machinery will by necessity replace costly hydraulic manual rotating systems.